- Quickly back to full production speed

- Case description:

After a modification to increase energy efficiency, the client is worried about excessive vibrations in their tissue machine. These high vibrations on the vacuum press roller and the adjacent guide roller (over 20 mm/s eff.) led to the client deciding to throttle the production speed of the system. A quick solution to the problem had to be found. Since the client suspected that the drive system (with cardan shaft) was causing the vibrations, the company contacted Off-Highway Powertrain Services (OHP Services) to identify the problem.

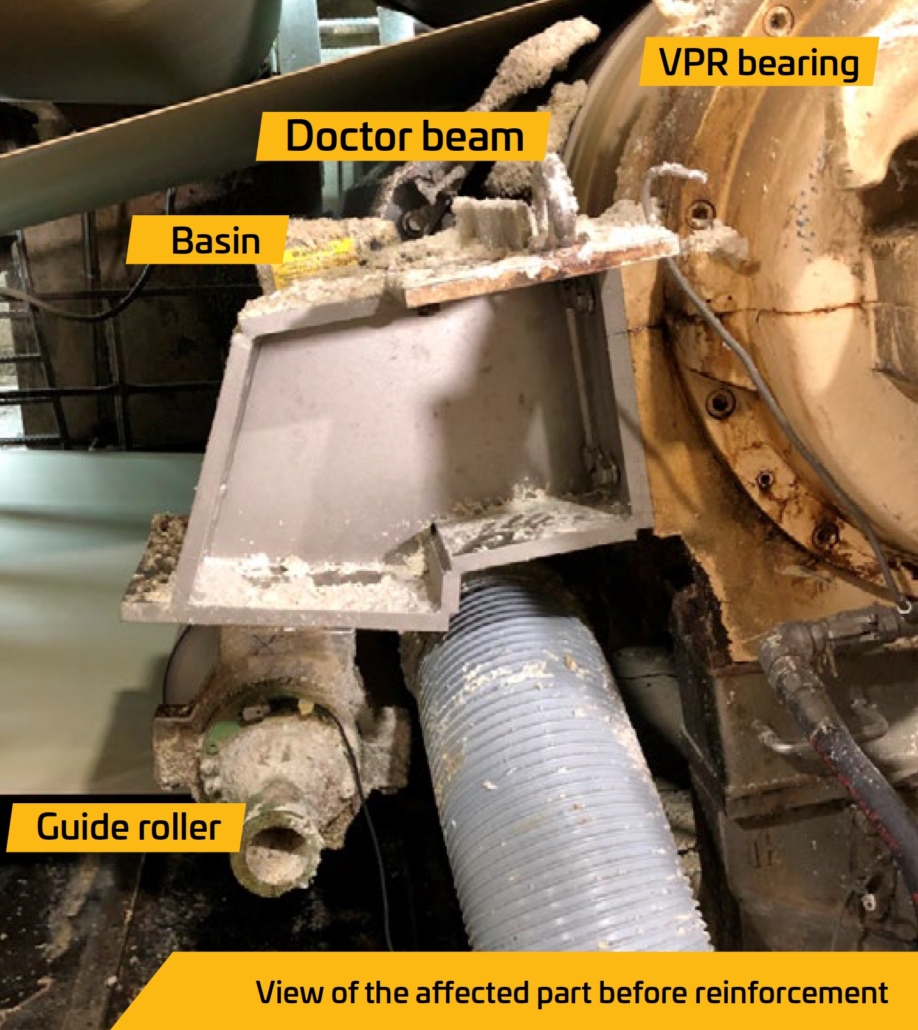

Shortly thereafter, a series of measurements were taken on site. During the first multichannel measurement, a structural resonance was found at full production speed. Furthermore, it was determined that incorrect installation (improper alignment) of the cardan shaft was not the cause. A testing plan was then developed for a second run. This included multiple measurements and the systematic restructuring of multiple components in the affected part of the tissue machine.

During the analysis of the measurement data, it was found that the problems were not simply the result of the modification of the system. With the systematic testing, the potential causes of the problem could be considerably narrowed down. It was recommended that the customer perform several tests the next time the rollers were replaced and reinforce the carrier structure of the guide roller.

Technological background:

OHP Services has multiple multichannel measuring systems that can be used in many different scenarios to measure vibrations, torques and other electrical variables. In combination with the highly qualified engineers who are also certified, experienced vibration analysts (up to ISO Cat IV), customers are provided with a valuable service offering.

The problem was solved quickly and efficiently with a structured series of measurements, which was developed with the client and fit well into the client’s production plan. The use of multichannel measuring systems with a variable sampling rate has proven effective compared to the use of only handheld measuring devices, since it enables simultaneous measurements on larger systems. This allows complex problems to be analysed more easily.

Challenge:

- Analysis of a very unclear problem with a very short lead time

- Working with the client to develop a structured solution

- Analysis of a complex structure with many influencing factors

Solution:

- Use of a multichannel measuring system and thorough analysis of the data led to the rapid identification of possible problems

- Development of a measurement plan with the client to individually localise the problems

- Creation of high-quality reports with specific recommendations that led to the problem being solved

Customer benefits:

- With the assistance of OHP Services, full production speed was quickly restored as the service could be performed at short notice

- State-of-the-art measuring equipment and highly qualified personnel from a provider that can also perform the recommended measures and provide spare parts

What made this case special?

- Many maintenance departments have portable vibration meters. However, their usefulness in analysing complex vibration problems is often very limited. Another problem is that personnel often do not have the time or the necessary experience to perform these analyses.OHP Services has its own dedicated department that specialises in complex measurement projects. In conjunction with the Field Service department, the client receives a complete range of services from a single source that includes the complex analyses, professionally performed repairs and a reliable replacement part service. We call this 360° Service. OHP Services is therefore an ideal partner when it comes to solving complex problems in the field of drive technology.