- }} Torque measurement on an airship propulsion

- Case description:

Off-Highway Powertrain Services (OHP Services) was asked by an airship manufacturer to investigate problems on failure-prone motor drive shafts. In the context of a development project the dynamics of the propulsion and the root cause of the failures was to be studied. After an extensive exchange of information regarding the operational conditions OHP Services recommended an analysis of the torsional vibration behavior and the torque.

For the measurement three different shafts were applied with strain gauges in the OHP Services lab. The telemetry, used to transfer data from the rotating to the nonrotating measurement system, was mounted on site. The measurements were carried out on different operational points that can be associated with different movements of the airship. The preliminary works and the measurements were carried out and monitored by a certified vibration expert of OHP Services.

The data acquisition and analysis was done on a data logger, specially configured by OHP Services to measure the torsional vibrations and the torque with the necessary precision and sampling frequency.

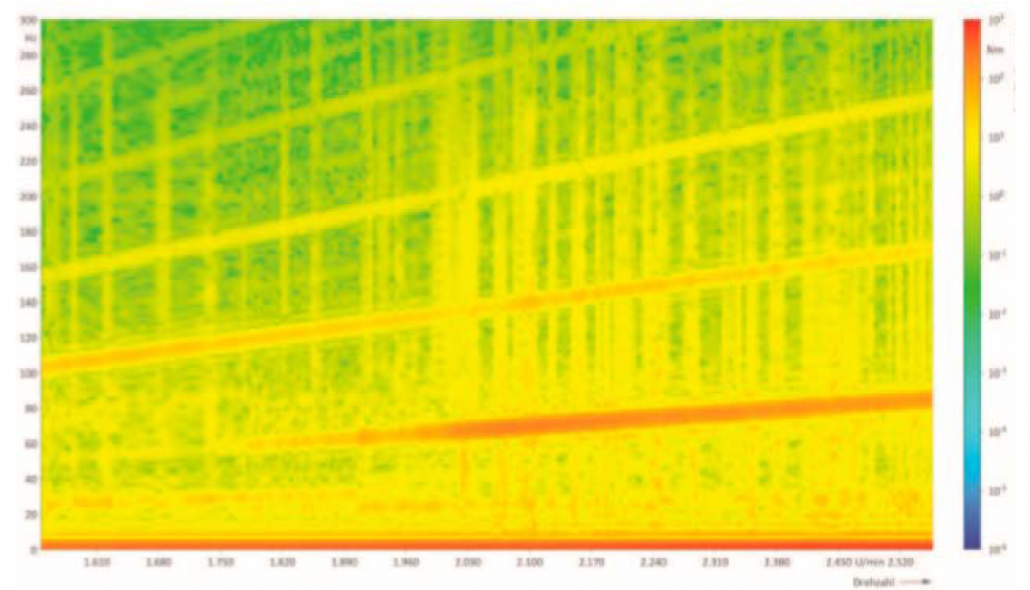

From the measured data Campbell diagrams were calculated for the most relevant operational points. With the Campbell diagram, which shows the Eigen frequencies in relation to the speed, the certified specialist of OHP Services could investigate the resonances of the drive configuration in the different operating points.

The analysis of the data demonstrated that no resonances in the operating points occurred, so they could not be the root cause of the problems. Further investigation of the data showed that two of the three investigated shafts had peak loads caused by the driving motor. The customer was advised to take measures to eliminate the influence of the driving motor. These measures could be performed by OHP Services too.

Challenge:

- Torque measurement in an extremely constrained and complex environment.

- Interference to the telemetry system caused by high mechanical vibrations and environmental conditions.

Solution:

- Mechanical preparation and preliminary configuration of the relevant drive parts in the OHP Services laboratory.

- Installation of the prepared drive parts and establishing the connectivity to the measurement equipment.

- Use of a bespoke torque measurement for the project.

- Accompaniment of the measurement process in all operational states to ensure a perfect signal recording.

Typical Campbell-Diagram with the excitation of the driving motor

Customer Value:

- The customer gained a deep and detailed understanding of the dynamic torsional behavior in all operational points of his drive.

- Detailed data analysis, prepared by OHP Services certified vibration experts, are the basis for optimization projects.

- Root-Cause solving advice was given to the customer by OHP Services.

What’s special?

- Due to the expertise of OHP Services a problem oriented measurement was carried out for the customers highly complex test rig. On the basis of the measurement data a specific solution for the problem was engineered and proposed to the customer.

- OHP Services does not provide “off the shelf” service! A highly complex and individual problem needs an individual and professional solution.