- Off-Highway Powertrain Services torque measurement service helps a transmission manufacturer to demonstrate the fuel savings of their new technology

- Case Description:

The customer promises up to 20 % fuel savings through the application of a new technology in automatic transmissions which they have developed. To convince their customers of this advantage, our customer conducted a test drive event, in order to compare the standard automatic gearbox to their new automatic gearbox. Therefore, they needed to measure total mechanical efficiency of two comparable trucks.

A very accurate fuel consumption analysis is needed to eliminate the external influences on the trucks e.g. from different drivers and wind strength. Torque measurement was used to relate the fuel consumption to the mechanical power of the cardan shaft.

Off-Highway Powertrain Services (OHP Services) as a preferred cardan shaft supplier and service provider was able to support the customer with the right cardan shaft together with integrated torque measurement technology.

Our service experts went on site to integrate the measurement technology into the truck’s control network. Now the customer is able to provide a live demonstration of the benefits of their new generation of automatic transmission to their end customers.

- Technology Snapshot:

Torque Measurement and Monitoring:

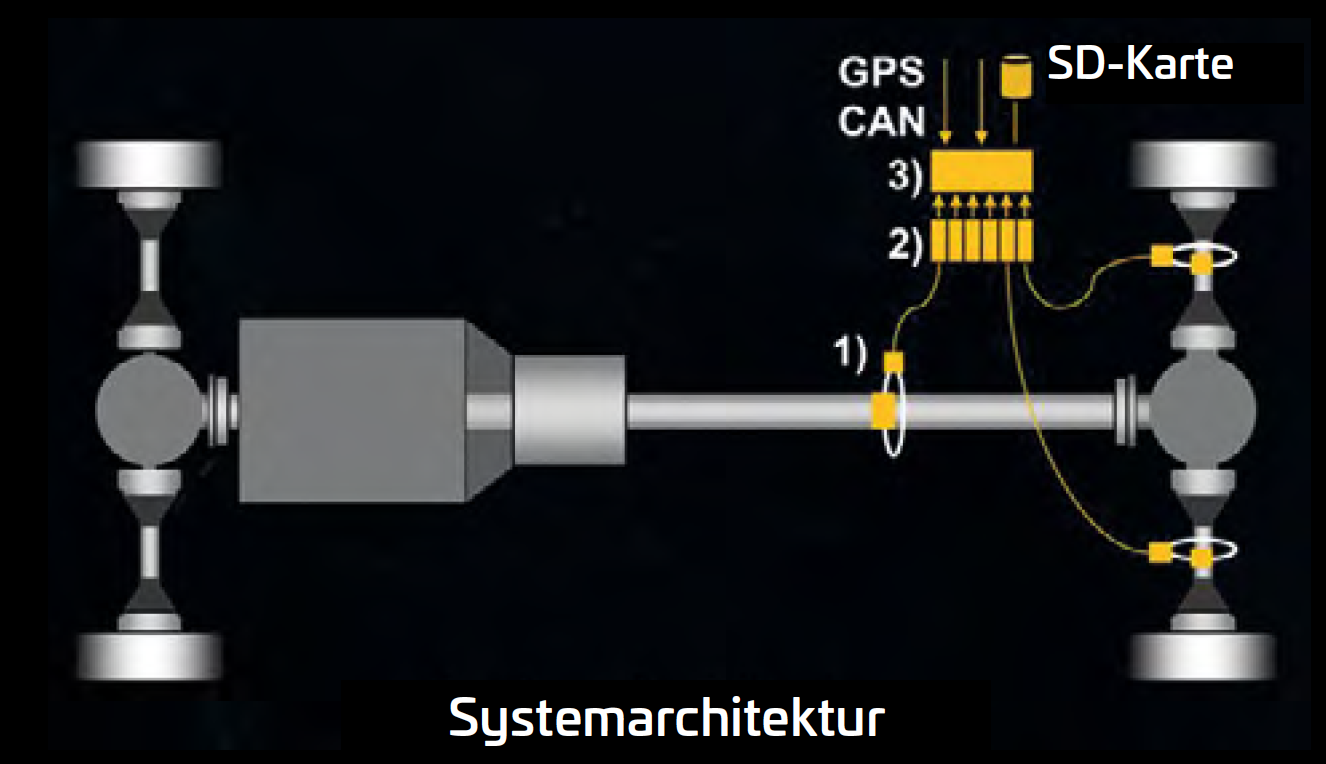

A telemetry unit is used for torque measurement on a rotating transmission shaft. The torque telemetry has a rotating part on the shaft that obtains the torque-induced strain from a strain measurement electronic device.

The torque signals can be provided to the truck control network (e.g. CANBUS) or directly to a data acquisition system (depending on the existing infrastructure and the project requirement). The torque signals can then be analysed and interpreted by OHP Services experts on a regular basis.

The customer receives a regular report containing the recorded torque signals, the torque events, the torque statistics (mean -, max torque, torque amplification factor, load spectrum) and damage indicators (as required and technically possible). To get a more detailed view of the powertrain condition, torque measurement can be combined with other measurement technologies like temperature, vibration and speed sensors, etc.

Challenge:

- Measure mechanical output torque and power of the automatic transmission

- Demonstrate fuel efficiency of a truck under consistent driving conditions

- Integrate required measurement technology into the truck

Solution:

- Plug and play solution: Cardan shaft with integrated torque measurement

- Integration of the measurement technology into the truck’s control network

- Calibration of the torque telemetry by OHP Services experts

Customer Value:

- Clear communication of the benefit to the end customer through live demonstration

- Complete solution by a single service provider

- Potential for further optimisation and fuel savings through better awareness of the truck’s power usage

- Design assessment and optimisation of the powertrain based on realistic life cycle data

What’s special?

- OHP Services offers torque measurement technology as a service to avoid fixed cost to the customer. After assessment of the design, based on realistic life cycle data, OHP Services is able to optimise the powertrain for a specific application.

- Impressed by our capabilities the customer has now decided to outsource his in-house project to OHP Services